CV91-TECNOCEMENT

High performance special white cement

Benefits

- Special white cement with very high resistance, hardness and flexibility performances.

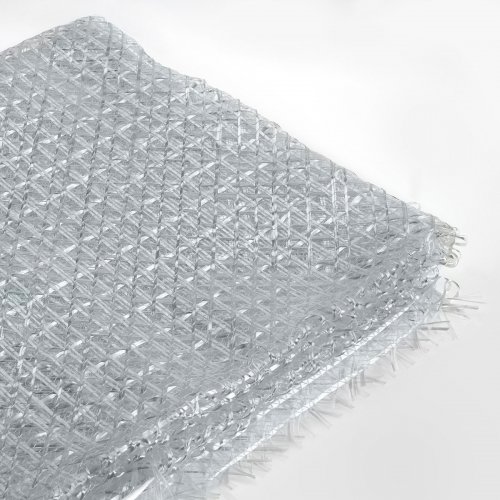

- Ready-to-use mixture, contains alkali-resistant anti-crack glass fibers.

- It can be colored in mass with pigments of mineral origin.

- It allows to obtain smooth and uniform surfaces guaranteeing a perfect reproduction of details.

- Particularly suitable for the realization of thin non-structural elements, casts and decorative elements / ornaments for outdoors.

CV91-TECNOCEMENT is a special high-performance cement, particularly suitable for making thin non-structural elements, casts and decorative elements such as worktops, bathroom and interior furniture, tubs, tiles and outdoor ornaments. Its formula allows to obtain perfectly smooth and uniform surfaces and an excellent reproduction of the texture of the casts used. Mixed with water in suitable stoichiometric ratios, it gives rise to a white mixture.

- Density of fresh mortar = 2.34 gr / cm3

- Cement / Water Ratio = 1 Kg: 0.11 L

- Granulometric size = 0 - 500 um

- Dynamic elastic modul after 28 days = 50 Gpa

Mechanical properties (average values obtained on 4x4x16 cm prisms)

- Compressive strength at 20 °: 1 day = 75 Mpa / 7 days = 110 Mpa / 28 days = 130 Mpa

- Flexural strength at 20 °: 1 day = 9-10 Mpa / 7 days = 13-18 Mpa / 28 days = 15-20 Mpa

CV91-TECNOCEMENT can be subjected to heat treatment after setting, which consists in subjecting the manufactured elements to a temperature that gradually rises between 60°C and 90°C over a period of time from 48 to 72 hours. This treatment allows to accelerate the maturation process of the material, contributing to the increase of the strength and durability of the material and giving CV91-TECNOCEMENT a high dimensional stability. CV91-TECNOCEMENT can be colored with pigments of mineral origin.

The preparation of the mixture with a mortar or cement mixer is carried out as follows:

- Pour the material into the mixer

- Knead 30 seconds

- Add 0.11 liters of water for every kg of Tecnocement

- Knead for 2 minutes (starting from the fluidization of the dough)

- Stop and scrape the walls of the mixer

- Knead another 2 minutes

- Pour without waiting for the mixture into the formwork to be filled.

- Always proceed in the same direction to avoid the formation of air bubbles.

It is recommended to use a planetary agitator.

Removal from the mold can be done after 18-24 hours. After removal, the pieces must be kept moist or immersed in water at 20°C for a few days. Avoid laying in dry, hot and windy places in the first few days.